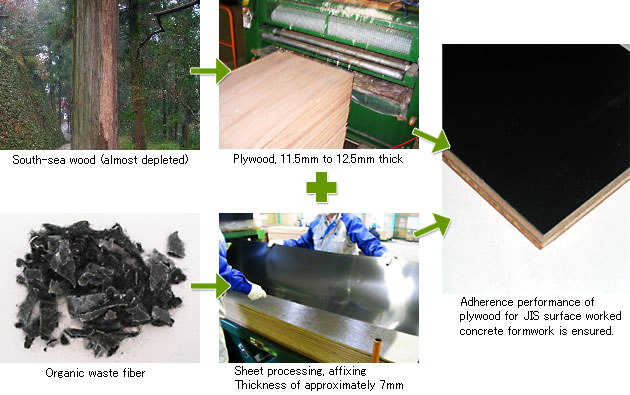

We adhere polypropylene sheets approximately 0.7 mm thick in which organic waste fibers are mixed, and plywood, and then ensure adhesion performance the same as that of plywood for JAS concrete formwork.

This sheet is thicker than the coating film of presently coated plywood, and greatly increases durability and the number of reuses, and facilitates finely finished concrete surfaces.

Moreover, it offers the same workability as conventionally coated plywood, and is easily handled.

Sheet sizes are 900mmx1800mm and 600mmx1800mm.

This special polypropylene sheet is resistant to alkalinity and heat generation of concrete, prevents wear and breakage on the surface of plywood and around corners, end grains, separator holes and nails in plywood, and further increases durability of plywood for concrete formwork in comparison with conventionally coated plywood.

The thickness of the polypropylene sheets coats wood grains and nodes on the surface of plywood, prevents transfer onto concrete surfaces and finishes concrete surfaces smoothly and finely without adherence of coating film and inclusion of plywood skin which is common with conventionally coated plywood.

This sheet is thicker than the coating film of presently coated plywood, and greatly increases durability and the number of reuses, and facilitates finely finished concrete surfaces.

Moreover, it offers the same workability as conventionally coated plywood, and is easily handled.

Sheet sizes are 900mmx1800mm and 600mmx1800mm.

This special polypropylene sheet is resistant to alkalinity and heat generation of concrete, prevents wear and breakage on the surface of plywood and around corners, end grains, separator holes and nails in plywood, and further increases durability of plywood for concrete formwork in comparison with conventionally coated plywood.

The thickness of the polypropylene sheets coats wood grains and nodes on the surface of plywood, prevents transfer onto concrete surfaces and finishes concrete surfaces smoothly and finely without adherence of coating film and inclusion of plywood skin which is common with conventionally coated plywood.

Until Katawaku-ecochan is completed

Comparison between Katawaku-ecochan and conventionally coated plywood after 15 times of reuse (exterior walls of multifamily housing unit)

| Conventionally coated plywood | Katawaku-ecochan |

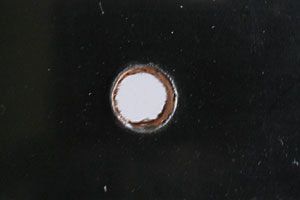

Around end grain, separator hole and nail |

Plywood |

Concrete surface |

Around end grain, separator hole and nail |

Inclusion of skin on plywood surface |

Concrete surface |

Workability is the same as that of conventionally coated plywood or better.

Nailing and saw cutting capabilities are same as

those of coated plywood.

Cutting ends around separator hole are smoother than that on coated plywood.

Thoroughly compatible with frames, and panel processing is the same as that for coated plywood.

Handling precautions

Make sure to use form release agent.

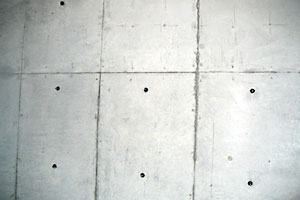

Inner wall of multifamily housing unit at removal

from formwork after 12 times of reuse

Inner wall of multifamily housing unit after scraping

work after 12 times of reuse.

This photo shows that a form release agent has spread.

Outer wall of multifamily housing unit built at 16 times of reuse

Recycle plastic fuel is obtained after use.

This recycle plastic fuel contributes to reductions in CO2 emissions as alternative energy for heavy oil fuel.

Recycle plastic fuel (RPF)